Aluminum Composite Panel

Aluminum Composite Panel Aluminum veneer

Aluminum veneer Aluminum Coil

Aluminum Coil Aluminum Ceiling

Aluminum Ceiling Powder aluminum veneer Powder aluminum veneer |

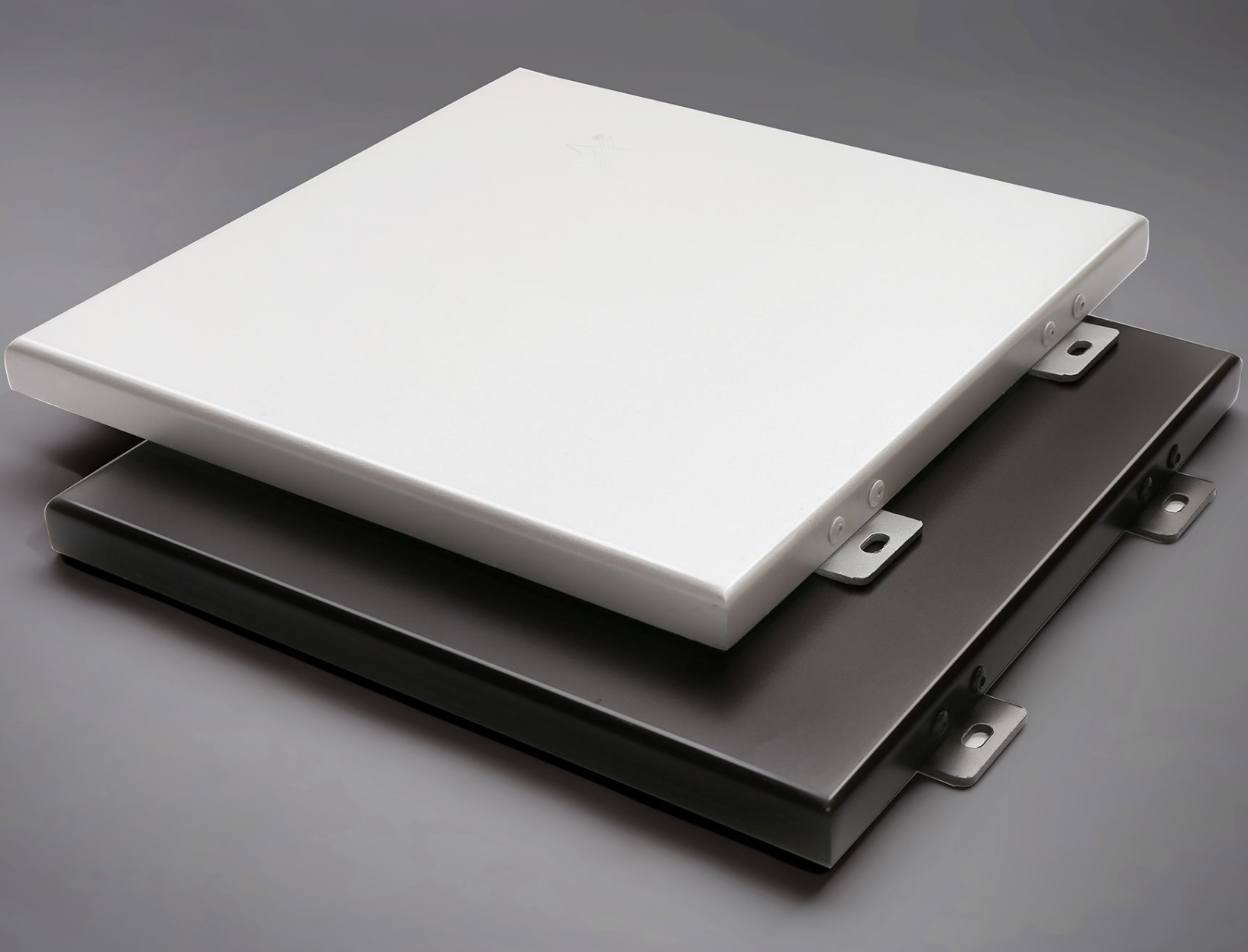

Products>Powder aluminum veneer |

The powder spraying is performed based on the principle of electrostatic spraying, through which dry powder can be absorbed onto the molded veneer product and the powder can be solidified into a layer of solid and bright coating after baking at a high temperature of more than 200℃, making the surface of the product flat, smooth and uniform in color. It is characterized by strong acid resistance, alkali resistance, abrasion resistance and other performances. The current products of the company include super weather resistant powder, thermosetting fluorocarbon powder and hot-melt fluorocarbon powder, etc.

Performance introduction:

1. Break through the problem of insufficient weather resistance of fluorocarbon powder in the industry. The high-performance PVDF fluorocarbon coating (powder type) has a fluorine content up to the national standard of 70% PVDF fluororesin, its weather resistance can reach the outdoor warranty of more than 20 years, and its coating performance meets or exceeds the AAMA2605 standard.

2. The surface effect is fully upgraded, the hardness of the coating can reach 2H-4H, and the paper tape test is more than 3000 times. The color difference is not affected by the external environment, and the leveling property reaches the standard of fluorocarbon paint. Wear-resistant and scratch-resistant performance has been greatly improved.

3. The production and application technology breaks through the technical bottleneck that powder-type PVDF fluorocarbon coatings cannot be used as high-content metal powders, and can make metal colors without reducing the fluorine content.

Features:

1. It contains no toxicity, no solvent and no volatile toxic substances, so there are no public hazards such as no pollution, no fire and no discharge of "three wastes", fully complying with the national environmental protection requirements.

2. Diversified colors.

3. The coating utilization rate is high, up to more than 95%, and the powder can be reused after recycling.

4. The coating is dense, has good adhesion, good impact strength and toughness, and has high coverage of edges and corners. It has excellent chemical corrosion resistance and UV resistance.

Field of use:

Theaters, exterior walls of large buildings, high-end commercial buildings, gymnasiums, airports, railway stations and subway stations, etc.

Technological parameters:

| Liquid fluorocarbon spraying (2 coatings) | Average film thickness ≥30um, minimum local film thickness ≥25um |

| Liquid fluorocarbon spraying (3 coatings) | Average film thickness ≥40um, minimum local film thickness ≥34um |

| Liquid fluorocarbon spraying (4 coatings) | ≥65um |

| Powder (fluorocarbon) | Minimum local film thickness ≥30um |

| Powder (polyester) | Minimum local film thickness ≥40um |

| Powder (fluorocarbon) | Minimum local film thickness ≥40um |

| Resistant to artificial accelerated aging | Color difference ≤3.0 |

| Appearance quality | No surface defects such as flow marks, cracks, bubbles, paint slags, etc. |

|

HOME | ABOUT US | PRODUCTS | CONTACT US | Copyright © Taizhou Xingthai New Materials Co., Ltd. All Rights Reserved |