Aluminum Composite Panel

Aluminum Composite Panel Aluminum veneer

Aluminum veneer Aluminum Coil

Aluminum Coil Aluminum Ceiling

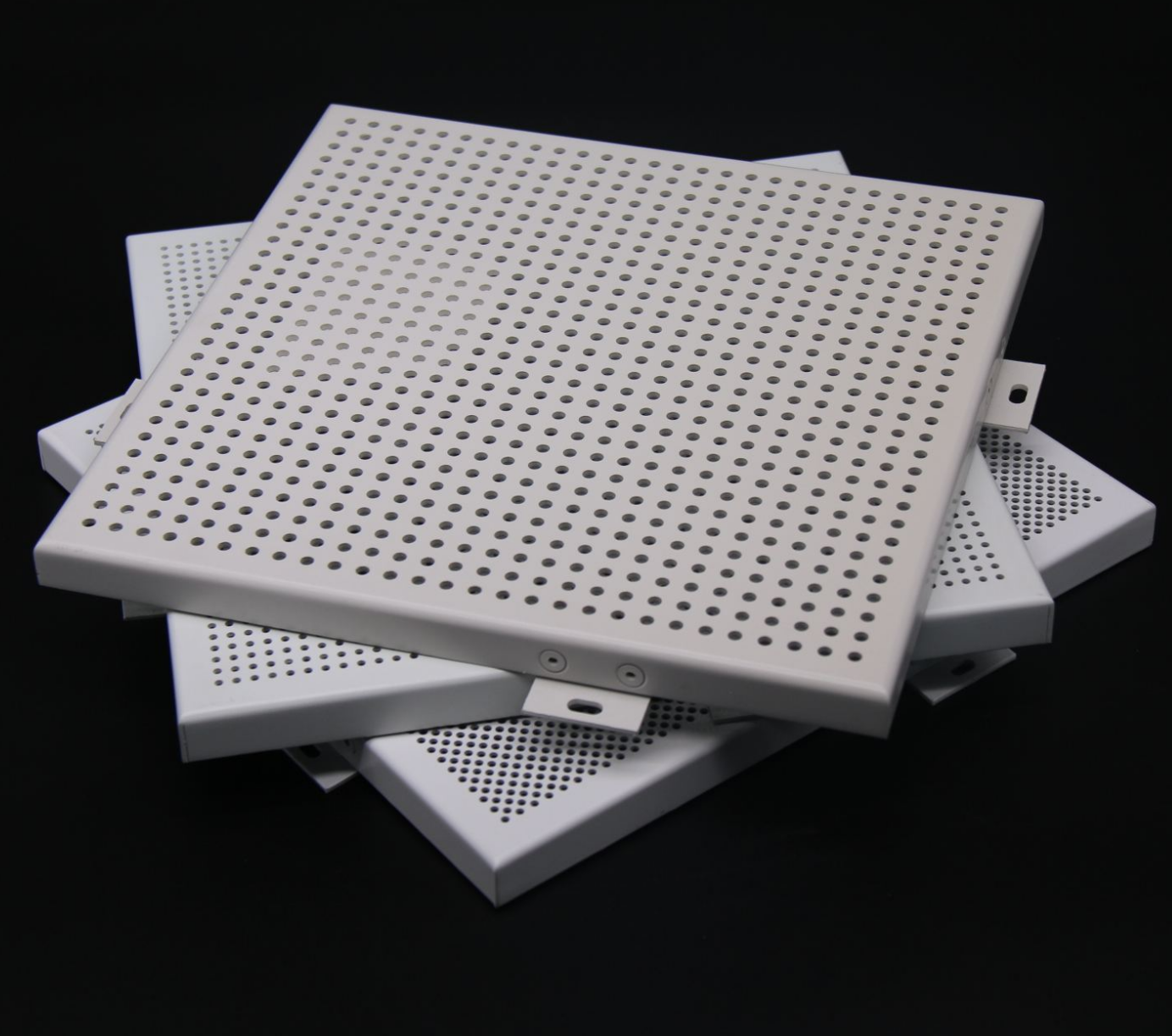

Aluminum Ceiling Perforated aluminum veneer Perforated aluminum veneer |

Products>Perforated aluminum veneer |

The perforated aluminum veneer is made of high-quality 1100, 3003, and 5005 aluminum alloy veneer as the base material, punched, molded on a CNC punching machine and then sprayed. The main hole shapes are round, square, prismatic, triangular, pentagram, oblong, square, honeycomb, etc. It can also customize and process a variety of complex hole shapes and modulation colors according to engineering drawings, which can meet the decorative needs of different buildings and better express the design concept and architectural style.

Features:

1. Light weight, good rigidity, strong weather resistance and corrosion resistance, not easy to fade, and good processing performance.

2. Strong three-dimensional sense, realistic image can be processed into various geometric shapes such as arcs and curved surfaces.

3. No need to cut at the construction site, just fix it on the skeleton, low maintenance cost, long service life and environmental protection.

Field of use:

Interior and exterior aluminum veneer decoration projects for high-end commercial buildings, stadiums, theaters, schools, airports, railway stations, subway stations, museums, etc.

Technological parameters:

| Liquid fluorocarbon spraying (2 coatings) | Average film thickness ≥30um, minimum local film thickness ≥25um |

| Liquid fluorocarbon spraying (3 coatings) | Average film thickness ≥40um, minimum local film thickness ≥34um |

| Liquid fluorocarbon spraying (4 coatings) | ≥65um |

| Powder (fluorocarbon) | Minimum local film thickness ≥30um |

| Powder (polyester) | Minimum local film thickness ≥40um |

| Powder (fluorocarbon) | Minimum local film thickness ≥40um |

| Resistant to artificial accelerated aging | Color difference ≤3.0 |

| Appearance quality | No surface defects such as flow marks, cracks, bubbles, paint slags, etc. |

|

HOME | ABOUT US | PRODUCTS | CONTACT US | Copyright © Taizhou Xingthai New Materials Co., Ltd. All Rights Reserved |